Innovating dental implants: How collaboration is driving a new era in oral health

Dental implants have transformed modern dentistry, offering patients a reliable solution for missing teeth. These titanium “screws,” first introduced by Dr. Per-Ingvar Brånemark more than 60 years ago, boast success rates as high as 98 percent. Yet, despite decades of innovation, one persistent challenge remains: peri-implantitis.

Peri-implantitis is a bacterial infection that erodes the bone supporting an implant. Current treatments such as cleaning, flap surgery, or implantoplasty (smoothing the implant surface) can be unpredictable and invasive. If these therapies are unsuccessful, the implant may get loose and fall out.

A new approach: modular implant design

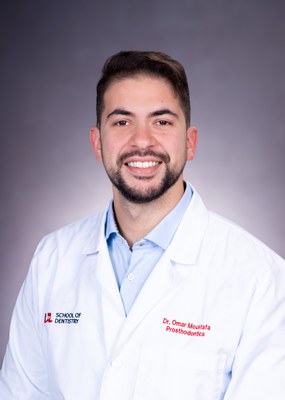

Recognizing the limitations of current peri-implantitis therapies, Dr. Omar Moustafa – a prosthodontist and researcher at the University of Louisville School of Dentistry – envisioned a better solution: an implant design modification, now under provisional patent as “Reattach,” that may offer a solution for patients at high risk of peri-implantitis.

Recognizing the limitations of current peri-implantitis therapies, Dr. Omar Moustafa – a prosthodontist and researcher at the University of Louisville School of Dentistry – envisioned a better solution: an implant design modification, now under provisional patent as “Reattach,” that may offer a solution for patients at high risk of peri-implantitis.

The inspiration for this breakthrough was surprisingly simple: “It came to me during residency,” Moustafa (pictured at right) says. “We had a patient with early implant failure, and I thought, what if we could modify the implant design?” After discussing and fine-tuning the idea with a fellow resident at The Ohio State University, Dr. Hassan Alamri, Dr. Moustafa set out to bring it to life after he joined the faculty at the University of Louisville School of Dentistry in 2024.

Speed School collaboration brings the idea to life

Turning this idea into reality required engineering expertise. Enter the Additive Manufacturing Institute of Science & Technology (AMIST) at UofL’s Speed School of Engineering. “I gave them the basic implant shapes and explained my concept,” Moustafa recalls. “They helped me model it and then performed finite element analysis to ensure the design wouldn’t fail mechanically.”

The collaboration involved AMIST Coordinator Justin Gillham and engineering student Owen Mattingly, who handled much of the design work under Moustafa’s and Gillham’s guidance. Within six months, the team produced a prototype – a large-scale plastic model that could then be handed off to a manufacturer to create titanium versions at actual implant size.

While the design and development stages have moved quickly at the University of Louisville, it will still take some time for the product to reach the market. “Because it goes in the human mouth, it’s considered a medical device – so it has to go through bench studies, animal testing, and then human trials before receiving FDA clearance,” Moustafa explains.

From a spark of an idea to a promising prototype, this project exemplifies the power of interdisciplinary collaboration. “Engineering helped make the concept a reality,” Moustafa says. If successful, it could offer new options in dental care for decades to come.

The partnership with the School of Dentistry reflects AMIST’s broader mission to foster interdisciplinary cohesion across the University of Louisville. While housed within Speed School, AMIST routinely works with researchers and practitioners from across campus to apply engineering tools to challenges in health, athletics, and industry. These collaborations allow experts from different fields to translate domain-specific knowledge into manufacturable solutions, whether improving medical devices, enhancing athletic performance, or advancing materials research. Projects like the modified implant design highlight how cross-disciplinary teamwork can unlock new approaches to long-standing problems.

This project received funding through the National Institutes of Health (NIH) Mid-South REACH program

January 22, 2026

By Paige Moore